Save time, money and increase productivity with the right wheel loader Bucket for your application. Wheel Loader Buckets are built to match different application requirements. Use high strength steel and wear-resistant steel can increase the durability and service time. With over 20 years’ experience in the attachments industry, we can help you select the right buckets for your excavator.

Specializing in the production of various construction machinery structural parts, which can be customized.

EDCM offers wheel loader buckets and attachments to fit most wheel loader models. All our buckets are built to a high specification, so you get more for your money.

Q355B/Q690D/NM400/HARDOX

| Type | Excavator Model | Ton | Width/MM | Capacity/M3 | Weight/KG | Adapter |

| S | CAT930H | 13T | 2620 | 2.0 | 960 | Bolt-on BOCE |

| S | CAT938H | 15T | 2670 | 2.6 | 1230 | Bolt-on BOCE |

| S | CAT950H | 18T | 2905 | 3.50 | 1570 | Bolt-on BOCE |

| S | CAT966H/972H | 24T | 3010 | 4.30 | 2445 | Bolt-on BOCE |

| R | CAT980G/H | 30T | 3410 | 4.50 | 3970 | Bolt-on blade lips and side cutters |

| R | CAT988G/H | 50T | 3850 | 7.70 | 6600 | Bolt-on blade lips and side cutters |

| R | CAT990H | 78T | 4490 | 9.00 | 9780 | Bolt-on blade lips and side cutters |

| R | CAT992K | 100T | 4680 | 12.30 | 11550 | Bolt-on blade lips and side cutters |

| R | WA600 | 54T | 3680 | 6.00 | 6250 | Bolt-on blade lips and side cutters |

| R | WA800 | 100T | 4900 | 11.00 | 12410 | Bolt-on blade lips and side cutters |

Loader bucket is mainly applied for unloading, shovel loading, transporting soil, rocks and coals. We use high strength and wear-resistant steel. so the loader has a long service life. It can also involve in working on the rock, hard ground for mild shovel digging operations. For different devices, it can also complete the bulldozing, lifting, loading and unloading, screening of other materials.

Cutting(plasma cutting machine/laser cutting machine) |

Pre-treatment——shot-blasting |

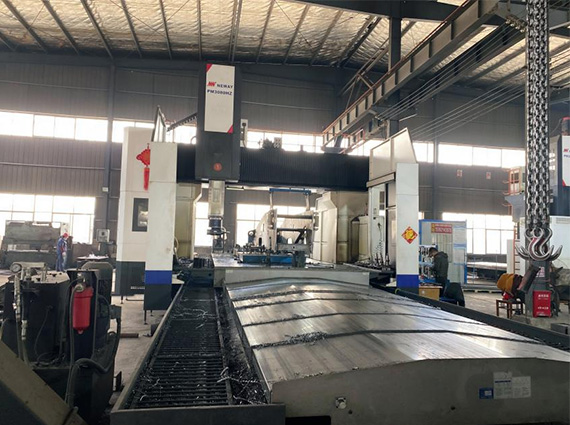

Machining |

Welding (qualified & certified welders) |

Surface treatment—sand blasting |

Painting |

Quality inspection |

Packaging Packaging |

Shipping Shipping |

DO NOT settle for our product lists! You can always customize the ideal excavator attachments for your own machine! We have expert team to follow your product drawings and customize the excavator buckets for you!