Save time, money and increase productivity with the right Excavator Bucket for your application. Excavator Buckets are built to match different application requirements. Choosing the correct match will ensure increased productivity and performance is maintained over the lifetime of the product. We have a full range of excavator buckets for machines from 1-85 tonne. Included in the range is mini excavator buckets, digging buckets, grading buckets, angle tilt buckets and trapezoidal buckets. With over 20 years’ experience in the attachments industry, we can help you select the right buckets for your excavator.

Specializing in the production of various construction machinery structural parts, which can be customized.

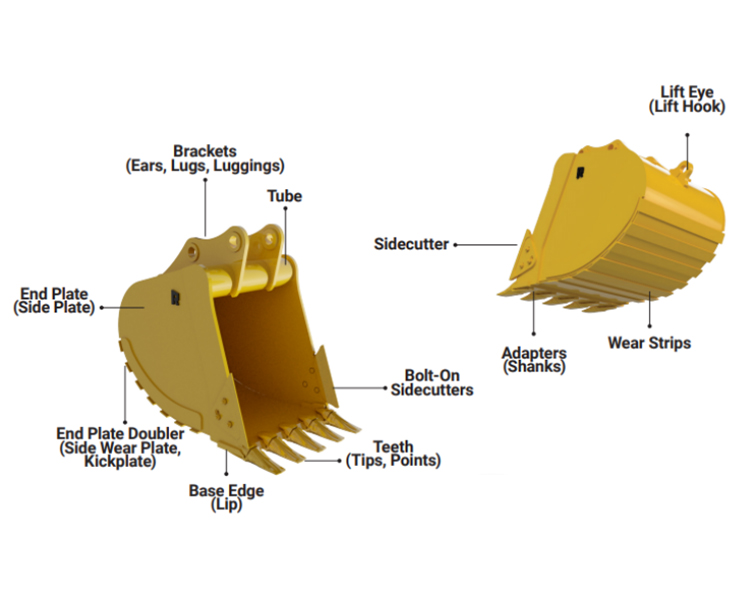

A heavy duty rock bucket is an excavator or loader attachment. Specifically designed to handle heavy or dense materials. Examples include rocks, stones, and boulders. It features reinforcement with high-strength materials such as steel and additional wear plates. To withstand the pressure and impact of heavy excavation work. Buckets are usually equipped with teeth or handles. To assist in digging and tearing tough materials. It also has a larger capacity than standard buckets. Heavy-duty rock buckets are commonly used in construction, mining and quarrying applications.

Heavy duty rock bucket (HDR)

Q345+NM400

/HARDOX400

| Bucket Type | Suitable Machine | Capacity | Material | Teeth | Side

Cutters |

Bucket

Pins |

Wear Plate |

|

Mini bkt GP bkt HD BKT Rock BKT DC BKT |

3t ~ 150t | 0.5m³ ~ 8m³ | NM400

Q345 HARDOX400 |

Optional | Optional | Optional | Optional |

Add strengthen plate in the bottom. Add side protective plate, high quality tooth holder to reach high abrasion and bending ability. Teeth & side cutters are at your option.

Mainly use for mining hard gravel mixed with hard soil, hard stone or flint, after blasting or loading, heavy duty and other hard load operating environments.

| Type | Materials | Optional | Scope of application |

| GP Bucket | Q345 | Teeth + Side Cutter | Mainly use for excavating sand gravel, soil and other light load operating environments. |

| HD Bucket | Q345+NM400 | Teeth + Side Cutter | Mainly use for digging hard soil, mixing relatively soft stone and clay, soft stone and other light load operating environments. |

| Rock Bucket | Q345+NM400

/HARDOX400 |

Teeth + Side Cutter | Mainly use for mining hard gravel mixed with hard soil, hard stone or flint, after blasting or loading, heavy duty and other hard load operating environments. |

| Mini Bucket | Q345 | Teeth + Side Cutter | Light duty environment for small excavators |

| DC Bucket | Q345+NM400 | / | Used in river, pond and ditch environments. |

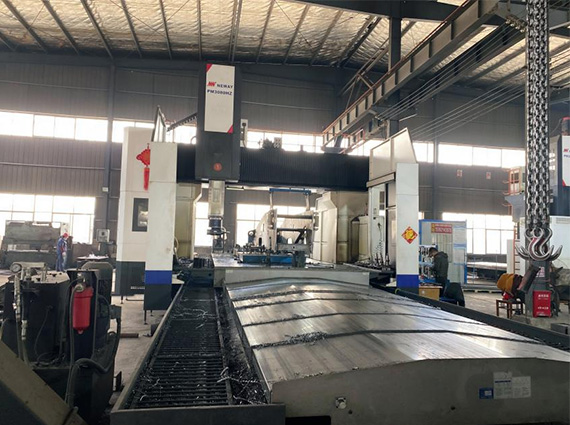

Cutting(plasma cutting machine/laser cutting machine) |

Pre-treatment——shot-blasting |

Machining |

Welding (qualified & certified welders) |

Surface treatment—sand blasting |

Painting |

Quality inspection |

Packaging Packaging |

Shipping Shipping |

DO NOT settle for our product lists! You can always customize the ideal excavator attachments for your own machine! We have expert team to follow your product drawings and customize the excavator buckets for you!