Save time, money and increase productivity with the right Excavator Bucket for your application. Excavator Buckets are built to match different application requirements. Choosing the correct match will ensure increased productivity and performance is maintained over the lifetime of the product. We have a full range of excavator buckets for machines from 1-85 tonne. Included in the range is mini excavator buckets, digging buckets, grading buckets, angle tilt buckets and trapezoidal buckets. With over 20 years’ experience in the attachments industry, we can help you select the right buckets for your excavator.

Specializing in the production of various construction machinery structural parts, which can be customized.

A mini bucket is a small attachment. Designed for mini excavators The mini barrel is a small accessory. Specifically designed for mini excavators or compact track loaders. It is often used for excavation work. It is often used for excavation work. It can work flexibly in narrow spaces. This is something that large equipment cannot do. Mini buckets come in a variety of sizes and configurations. Includes toothed or smooth edges. It can be use in a range of applications. Includes landscaping, construction and agriculture.

Mini bucket, EDCM offers mini excavator buckets and attachments to fit most excavator models. All our buckets are built to a high specification, so you get more for your money.

Q345

| Bucket Type | Suitable Machine | Capacity | Material | Teeth | Side

Cutters |

Bucket

Pins |

Wear Plate |

|

Mini bkt GP bkt HD BKT Rock BKT DC BKT |

3t ~ 150t | 0.5m³ ~ 8m³ | NM400

Q345 HARDOX400 |

Optional | Optional | Optional | Optional |

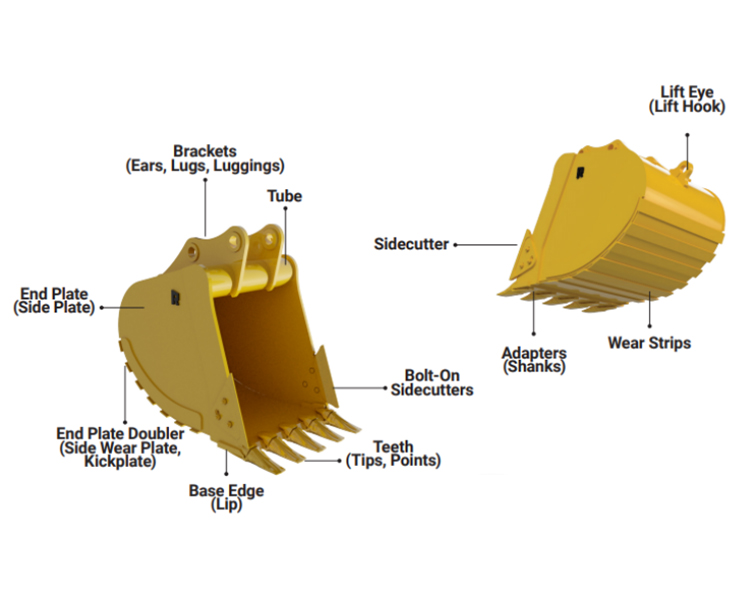

Bottom wear belts, Slim Design, Options in Bolt or Weld threads, Thick front edge cutter for extra strength and wear protection to help you get the most out of your sleeve. The lower wear belts exceed 90% of the bucket and provide more strength and protection. Teeth & side cutters are at your option.

Mainly use for Light duty environment for small excavators.

| Type | Materials | Optional | Scope of application |

| GP Bucket | Q345 | Teeth + Side Cutter | Mainly use for excavating sand gravel, soil and other light load operating environments. |

| HD Bucket | Q345+NM400 | Teeth + Side Cutter | Mainly use for digging hard soil, mixing relatively soft stone and clay, soft stone and other light load operating environments. |

| Rock Bucket | Q345+NM400

/HARDOX400 |

Teeth + Side Cutter | Mainly use for mining hard gravel mixed with hard soil, hard stone or flint, after blasting or loading, heavy duty and other hard load operating environments. |

| Mini Bucket | Q345 | Teeth + Side Cutter | Light duty environment for small excavators |

| DC Bucket | Q345+NM400 | / | Used in river, pond and ditch environments. |

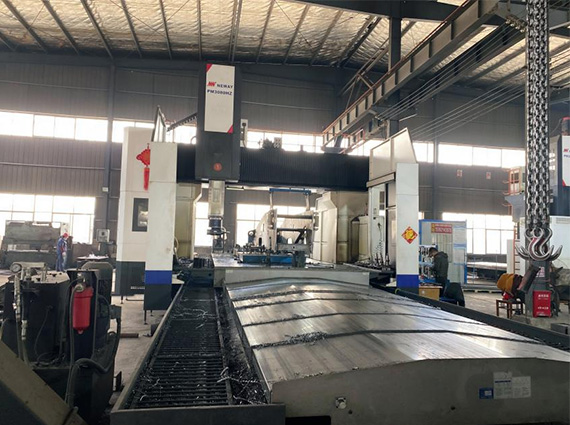

Cutting(plasma cutting machine/laser cutting machine) |

Pre-treatment——shot-blasting |

Machining |

Welding (qualified & certified welders) |

Surface treatment—sand blasting |

Painting |

Quality inspection |

Packaging Packaging |

Shipping Shipping |

DO NOT settle for our product lists! You can always customize the ideal excavator attachments for your own machine! We have expert team to follow your product drawings and customize the excavator buckets for you!

Q: What is a mini bucket used for?

A: Mini buckets are often used in tight spaces. Or an area that other large equipment cannot enter. It can be use for digging, grading, landscaping, and other applications.

Q: What sizes are mini buckets available in?

A: Mini buckets are available in various sizes, typically ranging from 6 inches to 24 inches in width.

Q: What types of edges do mini buckets have?

A: Mini buckets can have toothed or smooth edges depending on the intended use. A toothed edge is better for digging. Whereas smooth edges are better for grading or leveling.

Q: What are mini buckets made of?

A: Mini buckets are typically made of durable materials such as steel for long-lasting use.

Q: What machines are mini buckets compatible with?

A: Mini buckets are design to be compatible with mini excavators or compact track loaders.

Q: How do you attach and detach a mini bucket?

A: Mini buckets are typically attached and detached using a quick coupler system. Which allows for easy and fast changes between attachments.